Ultramid® A 218W V33 NATURAL T

聚酰胺 66 (尼龙66)PA66-GF33

德国巴斯夫-BASF Corporation

Ultramid® A 218W V33 Natural T is a polyamide 66, reinforced with 30% of glass fibre, heat stabilized, for injection moulding. The product is particularly recommended for the moulding of parts where some translucency is required, as well as surface aesthetics is important.

增强材料:玻璃纤维33%增强

含添加剂:热稳定剂

材料特性:易流动、Heat Stabilized - Organic、尺寸稳定、易脱模

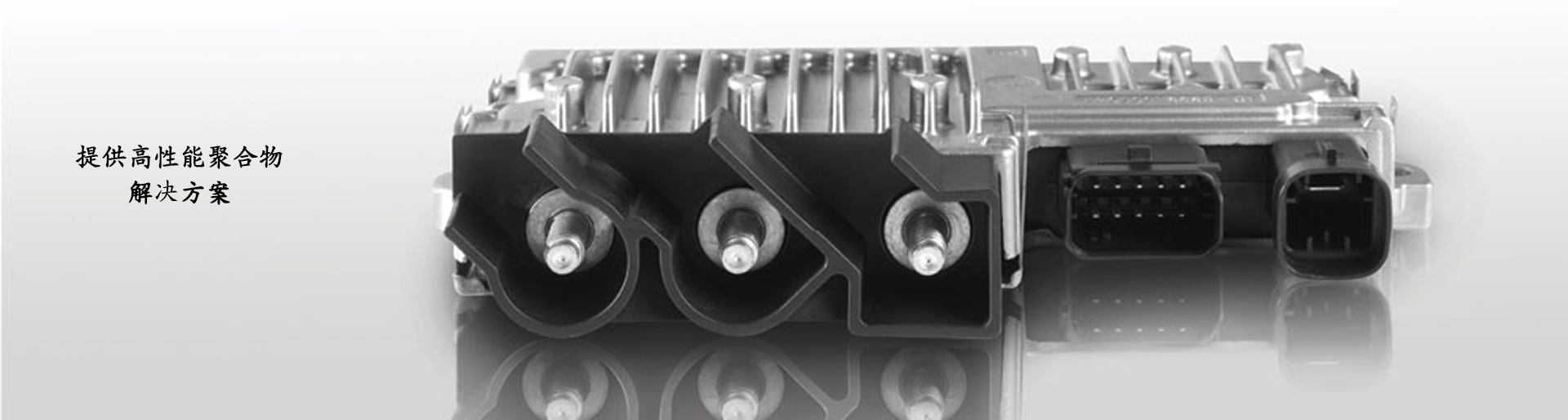

材料用途:连接器、线轴

加工方法:自然色粒子注射成型

供货地区:北美洲、非洲和中东、拉丁美洲、亚太地区

中国代理:苏州希普能工程塑料

Ultramid® A 218W V33 NATURAL T 加工参数表

| 物理性能 | 额定值 | 单位制 | 测试方法 |

| 密度 | 1.40 | g/cm³ | ISO 1183 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

| 拉伸模量 | 10200 | MPa | ISO 527-1 |

| 拉伸应力(断裂) | 190 | MPa | ISO 527-2 |

| 拉伸应变(断裂) | 3.8 | % | ISO 527-2 |

| 弯曲模量 | 8950 | MPa | ISO 178 |

| 弯曲应力 | 294 | MPa | ISO 178 |

| 冲击性能 | 额定值 | 单位制 | 测试方法 |

| 简支梁缺口冲击强度(23℃) | 11 | kJ/m² | ISO 179/1eA |

| 简支梁无缺口冲击强度(23℃) | 91 | kJ/m² | ISO 179/1eU |

| 悬壁梁缺口冲击强度(23℃) | 11 | kJ/m² | ISO 180/A |

| 热性能 | 额定值 | 单位制 | 测试方法 |

| 载荷下热变形温度 | |||

| 0.45 MPa,未退火 | 263 | ℃ | ISO 75-2/B |

| 1.8 MPa,未退火 | 247 | ℃ | ISO 75-2/A |

| 熔融温度 | 263 | ℃ | ISO 11357-3 |

| 注射 | 额定值 | 单位制 | |

| 干燥温度 | 80 | ℃ | |

| 建议的最大水分含量 | 0.20 | % | |

| 料筒后部温度 | 270 到 280 | ℃ | |

| 料筒中部温度 | 275 到 285 | ℃ | |

| 料筒前部温度 | 280 到 290 | ℃ | |

| 模具温度 | 70 到 100 | ℃ | |

| 注射说明 The material is supplied in airtight bags, ready for use. In case that the virgin material has absorbed moisture, it must be dried with a dehumidified air drying equipment, dew point mini -20℃. Recommended time 2-4h Injection Advice: For reinforced polyamides, BASF SE recommends the use of steel with a high content of carbon, and purified for polishing, to avoid or limit the abrasion. For example: X38CrMoV5-1 (EN Norm) - 1.2367 /1.2343 (DIN Norm) or X160CrMoV12 (EN Norm) - 1.2601 /1.2379 (DIN Norm). In the case of high requirements on surface quality a mould temperature of up to 120℃ can be considered. The processing parameters like processing temperatures are a recommendation and can be adjusted in function of injection machine size, part geometry / design |

|||