Ultramid® A3XZC3 ESD BK23187

聚酰胺66-尼龙PA66

德国巴斯夫-BASF Corporation

产品说明:

Ultramid® A3XZC3 ESD offers a wide range of properties that enable its use in ex-zones

An impact-modified, carbon fibre reinforced injection moulding grade with reduced surface resistivity. Flame retardance based on red phosphorus for components requiring enhanced toughness and special requirements on electrical properties.

-Electrostatic discharge

-Outstanding flammability properties

-Reduced surface resistivity

-Excellent mechanical properties

-Low density

•Lighter components with the same mechanical performance

•Potential cost savings

增强材料:碳纤维15%增强

材料特性:ESD(静电放电),阻燃

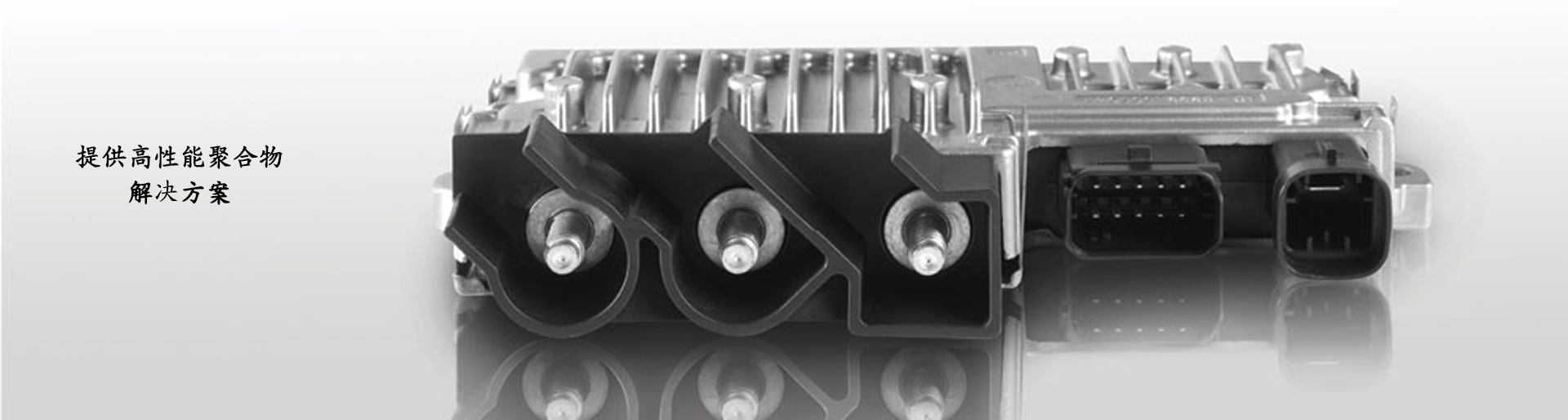

材料用途:工业防暴产品

加工方法:黑色粒子注射成型

供货地区:德国

中国代理:苏州希普能工程塑料

Ultramid® A3XZC3 ESD BK23187巴斯夫中文加工参数表

| Properties | Test method | Unit | Values |

| 聚合物缩写 | - | - | PA66-I CF15 FR(52) |

| 密度 | ISO 1183 | kg/m³ | 1190 |

| 熔体体积速率 MVR 300℃/10 kg | ISO 1133 | cm³/10min | 7 |

| Injection molding | Test method | Unit | Values |

| 熔融温度范围 | - | ℃ | 280-300 |

| 模具温度范围 | - | ℃ | 80-90 |

| Shrinkage | Test method | Unit | Values |

| 成型收缩率(平行) | ISO 294-4 | % | 0.5 |

| 成型收缩率(常态) | ISO 294-4 | % | 0.55 |

| 加工收缩,受限,纵向(TM=290℃,TW=80℃) 1 | - | % | 0.4 |

| 机械性能 | 测试标准 | 单位 | 数值 |

| 拉伸延伸率 | |||

| 标称断裂伸长率 | ISO 527-1/-2 | % | 4.0 |

| 拉伸模量 | ISO 527-1/-2 | Mpa | 10000 |

| 冲击性能 | 测试标准 | 单位 | 数值 |

| 简支梁缺口(Charpy Notched) | |||

| -30℃ (-22℉) | ISO 179/1eA | kJ/m² | 60 |

| 23℃ (73℉) | ISO 179/1eA | kJ/m² | 65 |

| 燃烧性能 | 测试标准 | 单位 | 数值 |

| UL 防火等级 | IEC 60695-11-10 | 1.6mm | V-0 |

| 灼热丝可燃性指数(GWFI)1mm | IEC 60695-2-12 | ℃ | 960 |

| 电学性能 | 测试标准 | 单位 | 数值 |

| 表面电阻率 | IEC 62631-3-2 | Ohm | 1.00E+06 |

| Footnotes 1 Model housing with central sprue, measures of the base:107x47x1.5mm. |

|||